ul 94v requirements izod impact test|ul 94 flammability : manufacturing LEXAN EXL9134 polycarbonate (PC) siloxane copolymer resin is a UV stabilized high flow opaque injection molding (IM) grade. This resin offers UL94 V0 @ 1.5mm flame retardancy based on non-bromine, non-chlorine FR systems, extreme low temperature ductility (-40 deg C) characteristics and excellent processability with opportunities for shorter IM cycle times .

O termo surgiu durante os anos 60 e chegou ao Brasil por volta de 1997 com um significado bem simples: vestir-se ao contrário. É um fenômeno bastante comum, embora a maioria dos adeptos prefira realizar o crossdressing às escondidas, devido o preconceito e o mau julgamento da sociedade. A maioria dos CDs mantém sua identidade de gênero.

{plog:ftitle_list}

Resultado da 25 de nov. de 2019 · 特别声明:以上内容(如有图片或视频亦包括在内)为自媒体平台“网易号”用户上传并发布,本平台仅提供信息存储服务。 Notice: The content above (including the pictures and videos if any) is uploaded and posted by a user of NetEase Hao, which is a .

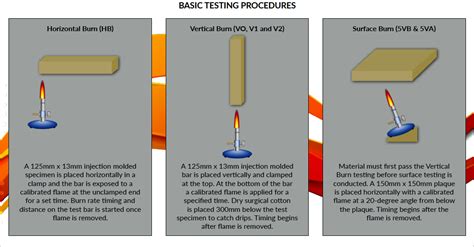

One of the most common tests, at least in the United States, of the physical characteristics of plastic materials is the notched izod impact test as specified by ASTM D256 Standard Test Method for Determining the Izod Pendulum Impact Resistance of Plastics.Complications associated with end-product flame testing tend to cause OEMs to look for materials with pre-selection (UL 94V / 5V) test ratingsUL 94 flammability testing is the first step toward obtaining a plastic recognition and subsequent listing in the "Plastics Recognized Component Directory" (former known as "Yellow Cards"). .The Izod Impact test, similar to the Charpy Impact test, is a method used to measure the energy immersed by the notched sample when it is struck by a pendulum. It is widely utilised for .

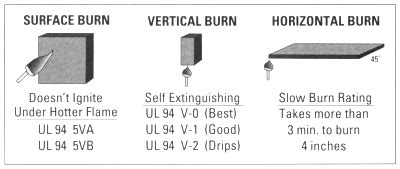

This test includes three classifications for assessing self-extinguished material: UL 94 V-0, V-1 and V-2, and would typically be acceptable for portable, unattended, intermittent -duty, .LEXAN EXL9134 polycarbonate (PC) siloxane copolymer resin is a UV stabilized high flow opaque injection molding (IM) grade. This resin offers UL94 V0 @ 1.5mm flame retardancy based on non-bromine, non-chlorine FR systems, extreme low temperature ductility (-40 deg C) characteristics and excellent processability with opportunities for shorter IM cycle times .

Accelerate your planning process and learn the requirements needed to take your products to market worldwide. Visit. myUL® Client Portal. . The Izod impact test is a quick and simple test to facilitate a comparative material . An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests .

abs water seal test

To determine the toughness, an XC-5.5D impact tester was used to perform the Izod impact test on the sample with dimensions of 63.5 × 10.16 × 6.35 mm 3 and a V-notch of 2.54 mm in depth. Melt .Meets FDA requirements in 21 CFR 177.1520 for all food contact, including cooking applications. . Izod Impact, Notched, ASTM D256A; Impact Test, Montell drop weight impact strength . UL RTI, Mechanical with Impact; Flammability, UL94; FDA, See notes for details. Property Data; This page displays only the text of a material data sheet. IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally .The basic features of the method for measuring Izod impact strength to ISO 180 are based on ASTM D256, however, it uses different specimen dimensions and provides a normative framework for both the measurement of impact strength on unnotched specimens, and notched impact strength and notch sensitivity on notched specimens. The ISO 180 standard supports the .

The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod andThe Izod test is a pendulum-based impact test named after an English engineer, Edwin Izod. The sample is held vertically as a cantilever beam and is struck with a hammer attached to a pendulum. The test gives us the impact resistance of the material. The test is conducted per the ASTM standards D256 and D4812 for notched and unnotched specimens .IMPACT TESTING MATTERS, NOW MORE THAN EVER 1.1 What is a Pendulum Impact Test An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester.Accelerate your planning process and learn the requirements needed to take your products to market worldwide. Visit. myUL® Client Portal. . UL Solutions offers a selection of mechanical test procedures, with an emphasis on automotive plastic materials: . Common standards for Izod impact test ISO 180, ASTM D256, or equivalent standards .

Similar to the Charpy Impact test, the Izod Impact test is a method used to measure the energy absorbed by a notched specimen when it is struck by a pendulum. It is commonly employed to test the impact strength of materials, especially plastics and polymers. During the Izod test, the sample is impacted in a vertical orientation at room temperature.

Charpy vs Izod An Impact Testing Comparison Element. Evaluating Fracture Surfaces from Charpy Impact Tests 3D. Toughness - Wikipedia. ASTM D256 Izod Impact Notched ISO 180. Class J - Charpy and Izod Automatic Impact Testing System - 1J .

GLASS FILLED POLYESTER UL 94V-0 (BLACK) PHYSICAL PROPERTIES ASTM TEST METHOD VALUES UNIT TEST RESULTS MECHANICAL Tensile Strength Elongation Flexural Modulus D638 D638 D790 110min 1.5min 7,800 Mpa % Mpa 131 OK 1.6 OK 11,380 OK IMPACT Izod,Notched D256 68min J/M 92 OK Thermal Deflection Temperature @1.8Mpa(264psi) .IZOD IMPACT PPT. II. TINJAUAN PUSTAKA. Impact Test Pengertiaan Metode dan Acceptance Criteria. 770 2863 1 PB PDF. Jasa Pengujian Impact Metode Izod dan Charpy. Pengujian impak dan fenomena PDF. ASTM D256 Plastik uji impact Izod berlekuk ZwickRoell. presentasi perbedaan uji impak charpy dan izod - YouTubeIzod impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. Izod specimens are notched to prevent deformation of the specimen upon impact. This test can be used as a quick and easy quality control check to determine if a material meets specific impact properties or to compare . In addition to impact, the IZOD test also provides an idea of the amount of energy the material can absorb. All of this is imperative to know before these materials are then turned into products or structures that people use .

This method is used to determine the UL 94 VTM-0, VTM-1 and VTM-2 flammability ratings of thin materials. Failure to pass the UL 94 V test is a precondition of all VTM ratings. The test evaluates both the burning and afterglow times and dripping of the burning test specimen. Standards for flammability UL 94 VTM UL 94 or equivalent standards

The Izod impact test is a type of test that measures the relative toughness of a material. Toughness in this context correlates to the material’s capacity to absorb energy. . The standard to follow depends on the impact testing requirements. There are differences between ISO and ASTM standards such as the units of measurement used. ISO/R 84-1959( E) Izod impact test for steel. International Organization for Standardization BS 131: Part 1: 1961 Methods for notched bar tests, Part 1 The Izod impact test on metals. . TEST REQUIREMENTS 6.1 The longitudinal axis of the test piece shall lie in the plane of swing of the centre of gravity of the hammer. .The Resil Impactor is a device used to conduct resilience test on thermoplastic materials, in order to determine their impact fragility characteristics under standard stress conditions. The Izod method, the specimen is supported as an embedded beam and is broken by a single oscillation of the pendulum at fixed distance from the specimen clamp .

Categories of the UL 94 Flammability Test. The UL 94 flammability test standard comprises 6 categories. These range from lowest to highest fire-resistant. Here are the standards: HB. This is a horizontal ignition test. It ceases before reaching 100mm. V-2. With this test, the ignition stops within thirty seconds. This happens in a vertical .

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog . The rating system was created by Underwriters Laboratories (UL), a safety consulting and certification company. The “94” in the rating refers to the UL 94 standard, which is used to test the flammability of plastic materials. The “V” stands for vertical, and indicates that the test is conducted with the material in a vertical orientation.

Hose Materials Flame-Retardant to UL 94V-0. Although some hoses are not UL 94V-0 registered and tested products, there are other hoses flame-retardant to our standard with many common uses and needs. These hoses are heavily used in shipyards – where UL 94V-0 registered hoses are not strictly required. These include:AS 1544.1—2003 2 PREFACE This Standard was prepared by the Standards Australia Committee MT-006, Mechanical Testing of Metals, to supersede AS 1544.1—1977, Methods for impact tests on metals,Learn more about Charpy & Izod Testing. Drop Weight Impact Test. A second method was to drop a weight in a vertical direction, with a tube or rails to guide it during the "free fall." . crack initiation, or complete fracture, depending on the requirements; These factors make falling weight testing a better simulation of functional impact .

ul94 flammability testing

Resultado da YouTube. YouTube是一個 視頻網站 ,早期 公司 位於 美國 加利福尼亞州 的 聖布魯諾 。. 註冊於2005年2月15日,由 美國華裔 陳士駿 等人創立,讓用户下載、觀看及分享影片或 短片 。. 2006年11月, Google 公司以16.5億美元 收購 了YouTube,並把其當作一家子公司來經營 .

ul 94v requirements izod impact test|ul 94 flammability